Hardened Steel ASTM F436 Washers – Quality Stamped in Cleveland, Ohio

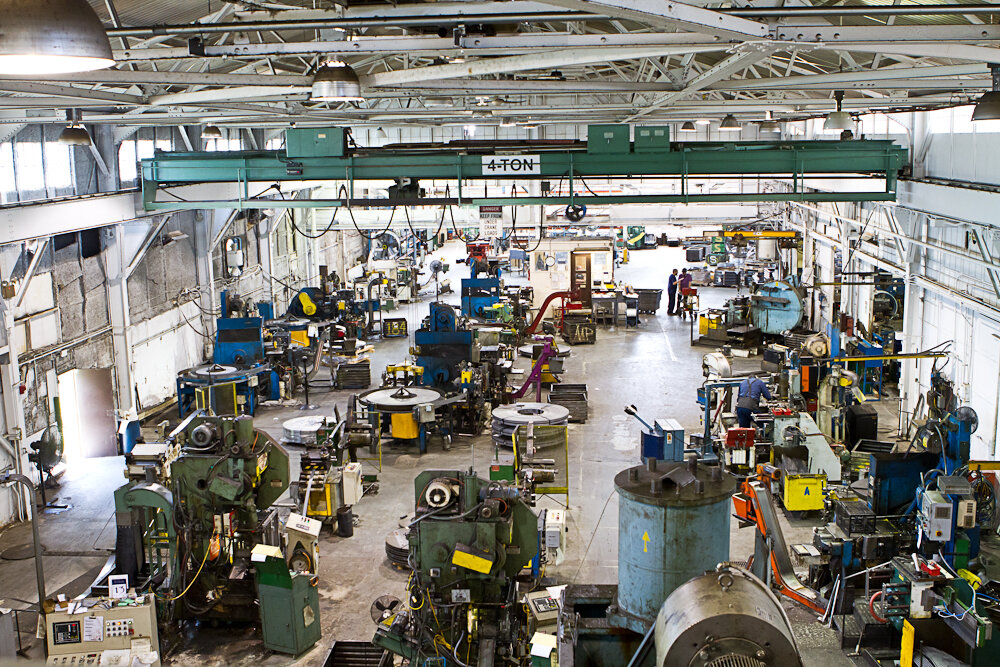

For over a century, Master Products has delivered quality American metal stamping solutions from our hometown in Cleveland, Ohio. While we offer diverse manufacturing experience in 99 unique Standard Industrial Classification (SIC) product categories, our primary product line consists of custom metal stampings and specialty washers.

With decades of superior metal-stamped quality under our belts, Master Products has evolved into one of the commercial industry’s most trusted suppliers of hardened steel washers.

Premium Hardened Metal Provider – ASTM F436 Washers (USS and SAE)

These hardened metal components – namely USS and SAE washers – have traditionally been the most high-volume production that Master Products is contracted to manufacture. These products include hardened steel ASTM F436 washers, as well as SAE Grade 8 and Grade 9 structural washers.

SAE Grade 8 vs. Grade 9 Hardened Steel Fasteners

Master Products is one of the Midwest’s leading contract manufacturers for structural washers and hardened steel fasteners in numerous SAE classifications. Two of our most commonly produced products include structural fasteners produced to Grade 8 and Grade 9 standards.

Both of these SAE classifications require the use of premium, reliable hardened steel, with Grade 9 being the more heavy-duty classification suited for high-performance industrial applications. For example, an SAE Grade 8 bolt must exhibit a minimum tensile strength of 150,000 PSI, while a Grade 9 bolt requires an even greater tensile strength of 180,000 PSI.

In-House Hardened Steel Stamping Services

Additionally, Master Products manufactures a complete range of other stamping products in-house such as machinery bushings (both narrow and wide-rim), shallow and regular cup expansion plugs, riveting/fending washers, as well as brass washers.

Your Domestic Metal Stamping Partner for Quality Hardened Metal Stampings

Proudly serving in the American metalworking industry since 1919, Master Products is your single-source contract manufacturer for quality, custom metal-stamped products.