Quality Machinery Bushings Are a Crucial Component for Today’s Metal Stamping Manufacturers

Today’s precision industrial tools, machinery, and equipment demands the highest quality wear parts and replacement components. That’s especially true when it comes to bearings, bearing surfaces, and spacers – a slight misalignment or an off-axis mating can easily wreak havoc on the machine’s performance and reliability.

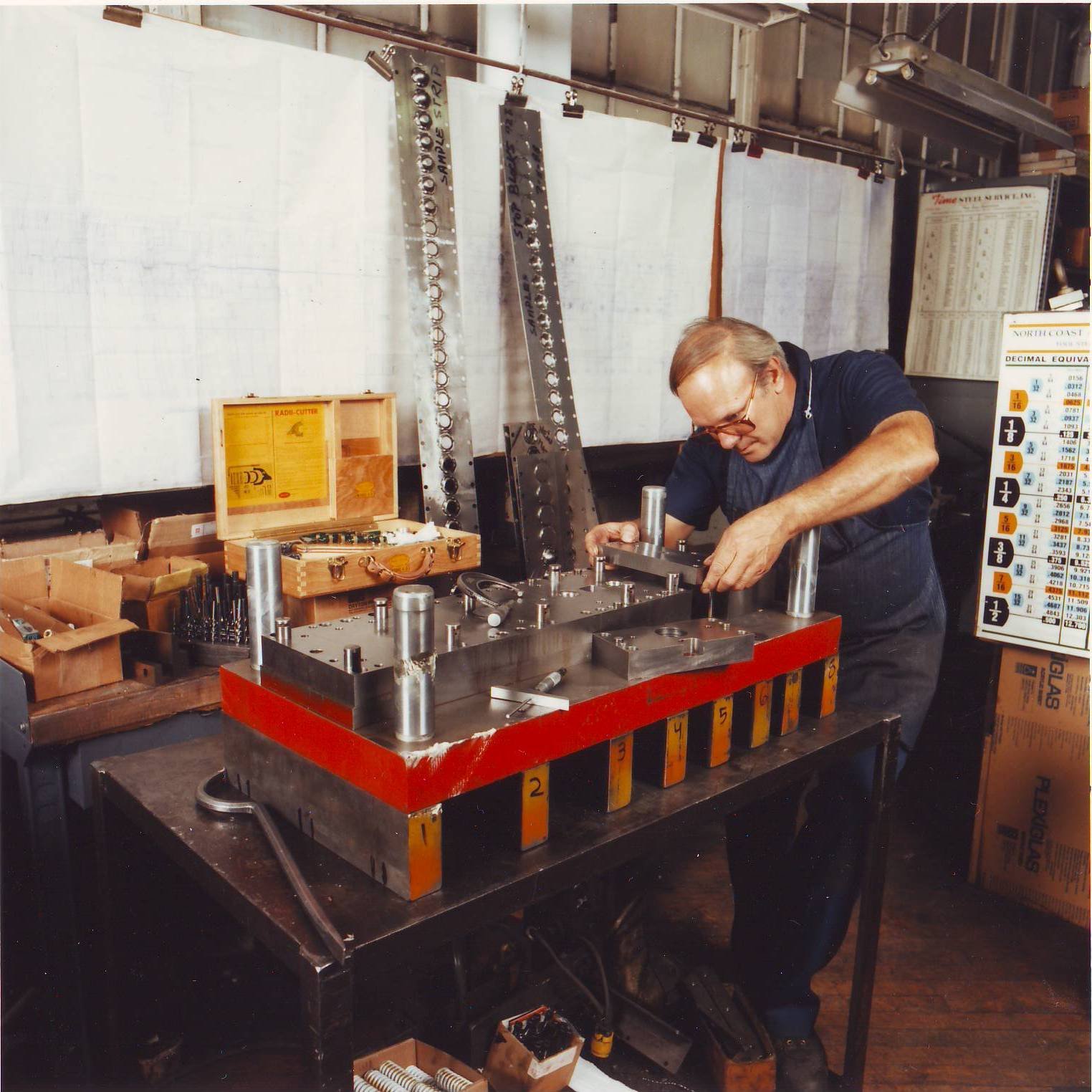

Master Products is a leading manufacturer of custom machinery bushings made in the USA.

What Are Machinery Bushings?

Machinery bushings are precision-formed shims of which feature specific diameters and thicknesses. Their general function is to provide accurate spacing on rotating shafts, while reducing wear between other moving parts installed on the shaft.

Also commonly known as plain bearings, machine bushings and shims generally feature an oversized outer diameter (OD) to create a larger bearing surface. The larger surface area promotes reduced wear between moving parts. At Master Products, we offer ample experience in manufacturing a wide range of machinery bushings in various gauges as well as different inside/outside diameters (ID/OD).

Machinery Bushing Types

Master Products commonly produces numerous unique configurations of machinery bushings for various custom metal stamping projects. The most common differentiator in machinery bushing types is the rim size specification, which allows the bushing to accommodate different sized machine components with narrow and wide faces:

Narrow-Rim Machinery Bushings

Plain bearings for narrow-face applications, with a rim that is generally less than 1” wide. Narrow-rim machinery bushings are commonly used small precision machinery and other equipment that utilizes miniature/micro bearings with tight spatial constraints.

Wide-Rim Machinery Bushings

Larger plain bearings with a rim that is generally greater than 1” wide. Wide-rim machinery bushings are common in many industrial equipment applications which utilize large bearing surfaces for increased stability, durability, and reliability.

Common Applications for Custom Machinery Bushings

Machinery bushings are precision stamped washers designed for use as quick, accurate spacing on shafts. The high-strength steel makeup reduces wear and marring between moving parts. Machine bushings are available in wide and narrow rim types for applications that require bushings with wide or narrow faces.

Mechanical Stamping Press Bushings

Hydraulic Stamping Press Bushings

Bushings for Material Handling Systems and Loading/Unloading Equipment

Production Line Machinery Bushings

Various Other Industrial Manufacturing Equipment Applications

An Experienced Machinery Bushing Manufacturer Based in Cleveland, Ohio

Master Products is one of the Midwest’s leading metal stamping companies providing custom machinery bushings along with a wide range of other stamped products. Our superior quality machinery bushings are made in the USA — manufactured in-house in Cleveland, Ohio, backed by more than 100 years of metal stamping excellence.