Progressive Die Stamping for Parts up to 72” – Pressed in Cleveland, Ohio

Master Products proudly remains one of the Midwest’s leading providers of quality progressive die stamping services. Our Cleveland-based production facility utilizes a wide range of industrial presses – 52 in total, operating between 15 and 250 tons – to provide the most cost-efficient and consistent metal stamping solution for your unique project.

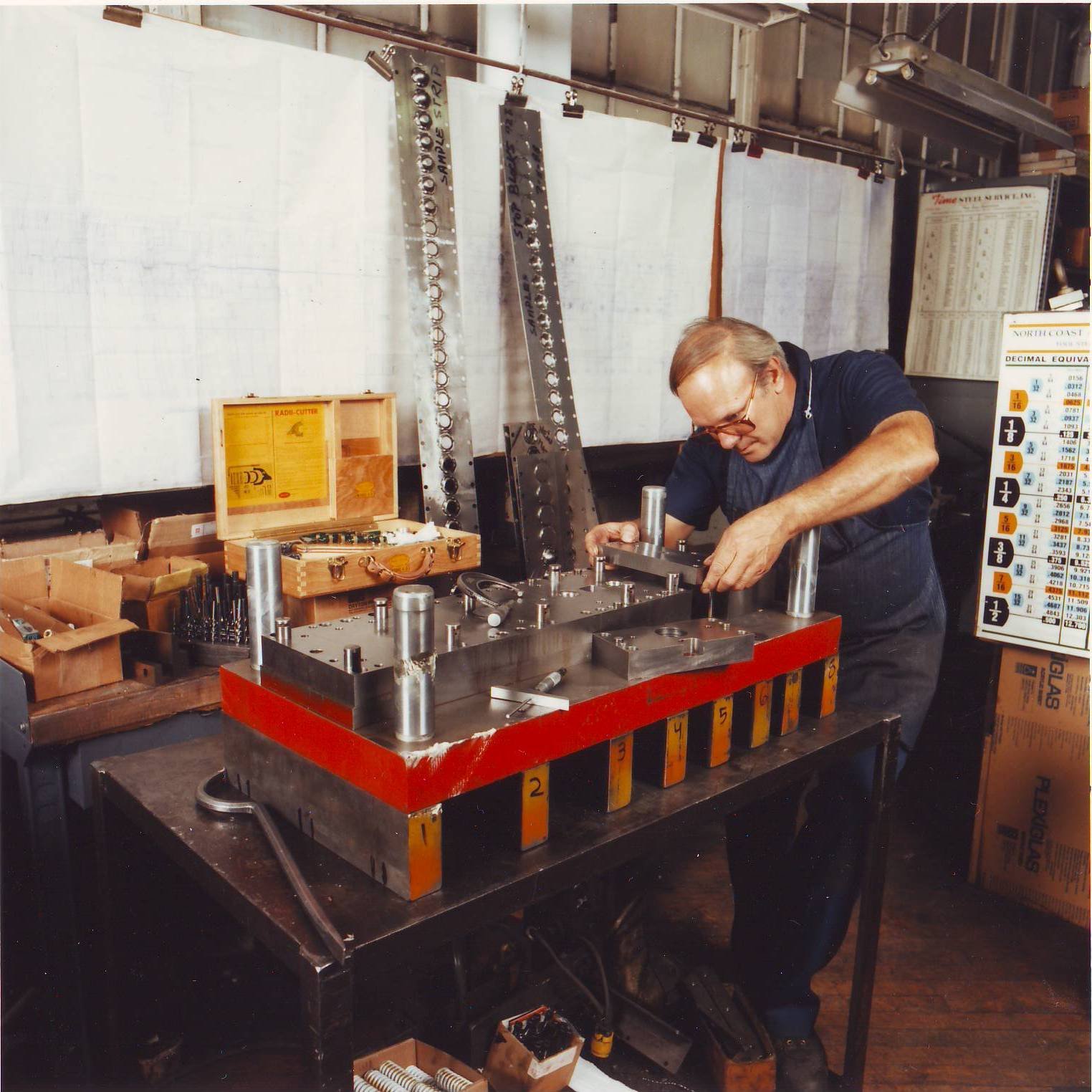

In many applications, complex products require our advanced progressive die capabilities, supported by our in-house tool room which builds and maintains all dies to Class-A standards.

The Advantages of Master Products’ Progressive Die Stamping Services

Streamlined Metal Stamping Solutions for Complex Components and Assemblies

Our progressive die capabilities enable us to streamline the manufacturing of your complex parts through a continuous, automatic stamping process.

Production times are minimized while consistency and repeatability are maximized to produce the highest quality parts as efficiently as possible.

Custom Tooling Manufactured and Maintained In-House to Class-A Die Building Standards

Custom tooling is the key to any successful progressive die stamping project. Precision-built tooling allows for more complex parts to be manufactured with closer tolerances.

Likewise, quality tooling ensures your custom metal stampings are produced with more consistency – especially important in high-volume stamping projects that require the utmost in repeatability between runs.

At Master Products, we build and maintain all of our progressive tooling in-house in accordance with Class-A die-building standards. We employ a staff of highly experienced toolmakers who design, modify, and optimize our custom tools for every progressive stamping project using the latest CAD systems and over a century of combined expertise.

Get in touch to discuss how Master Products can get your custom progressive stamping project off the ground and into production.